Looking

behind the (removed) glove compartment. Fan blower on the right.

Big black box in the middle houses the evaporative cooler.

Connector as annotated is the thermister and the amp circuit "in

line" in a small rectangular plastic box.

The

red arrow points to the paperclip I installed to bypass the thermister

transistor, which was telling the AC that the evaporator was always

frozen over, preventing the compressor from running.

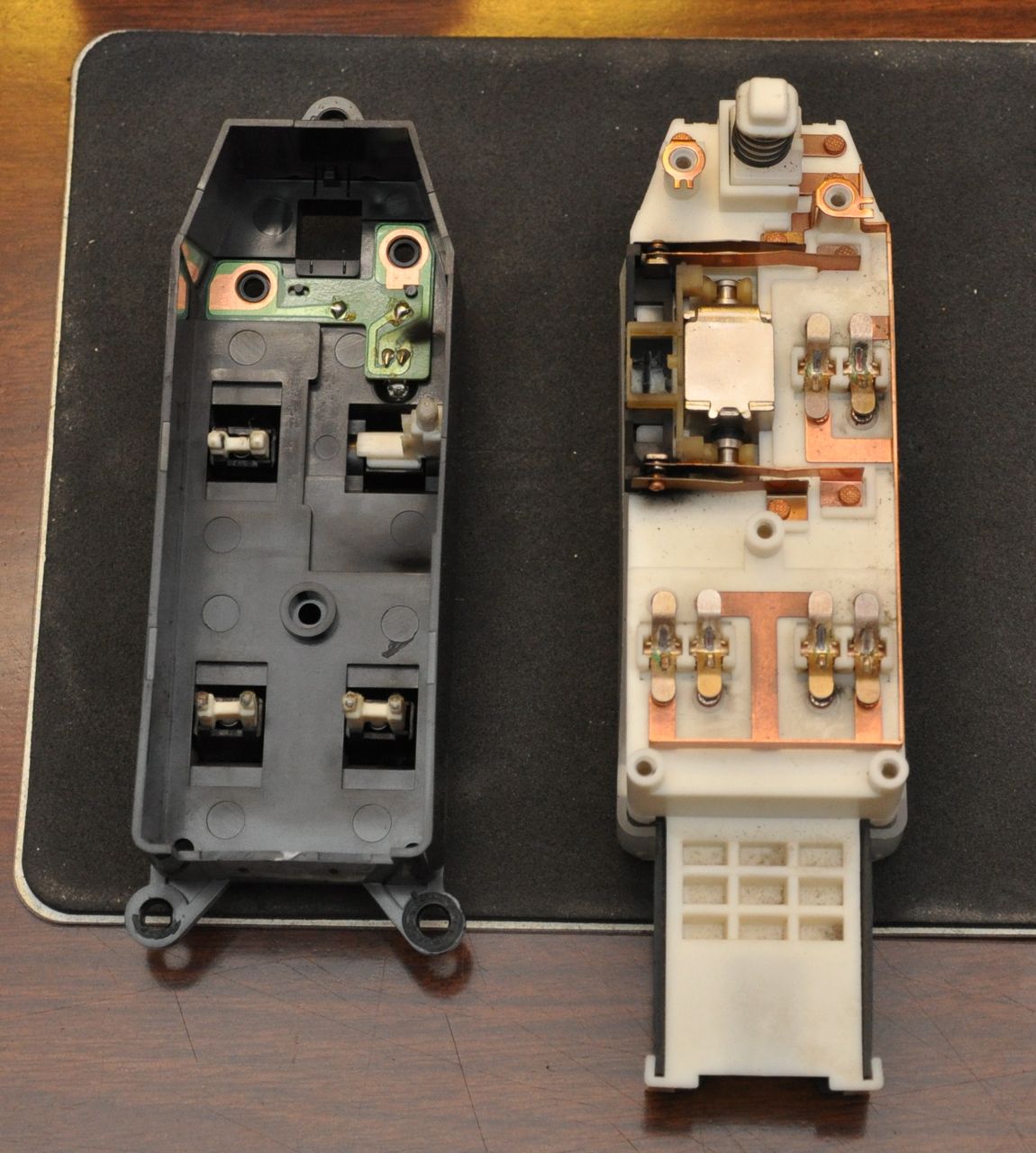

This is the window switch

module. White side is right side up, and the black top cover is

flipped over.

Electrical contacts were fine. The

problem was the two little broken ears shown to the right. You're

looking at the bottom side of the user toggles. The left one is

healthy.

Assembling the electrical switch

assembly back into the door.